Top-Level Research of Smart-Textiles

With leading edge research in the field of smart textiles the V-trion textile research GmbH has achieve an international reputation and promote the branch. The applications of smart textiles are extensive. They, for example, lie in the medical or health sector, where smart textiles can monitor tissue repair processes or transfer heart rates in a way that is more comfortable for the patient than traditional procedures. The research results enable access to new applications for high-tech materials, that strenghtens the Austrian textile industry within international competition and therefore also secures textile jobs in Austria.

SMART-TEXTILES RESEARCH PROJECTS 2021-2025

Many research projects of the Institute, that is managed by Dr. Gaffar Hossain, lead to commercial products as well as processes and support the local economy. Within the scope of cooperation projects with companies the Institute also opens up substantial funds

THE FUTURE ARE SMART-TEXTILES

SMART-TEXTILES GLOBAL MARKET

THE FUTURE ARE SMART-TEXTILES

Fiber-Composite

The composites market is expected to reach a market size of 80 billion 2025

Carbon composites are being preferred over alloys in vehicles to reduce overall weight and improve performance. Chemical corrosion resistance is another major advantage of these composites augmenting the demand for composites in the automotive industry. These composites also increase the versatility and durability of the vehicle without increasing its weight

Smart-Textiles

Global smart textiles in apparel market worth EURO 100 billion by 2025

The key growth areas will be initially sports and wellbeing followed by medical applications for patient monitoring and fashion. Technical textiles, fashion and entertainment will also be significant applications with the total market expected to rise to over Euro 100 billion by 2025 with triple digit compound annual growth rates across many applications

Nano-Technology

Smart-textiles use nanotechnology worth over EURO 130 billion by 2025

Advances in fields such as nanotechnology, organic electronics and conducting polymers are creating a range of textile–based technologies with the ability to sense and react to the world around them. This is creating a 4th industrial revolution for the textiles industry worth over Euro 130 billion by 2025

V-TRION THE SMART-TEXTILES INSTITUTE

THE FUTURE ARE SMART-TEXTILES

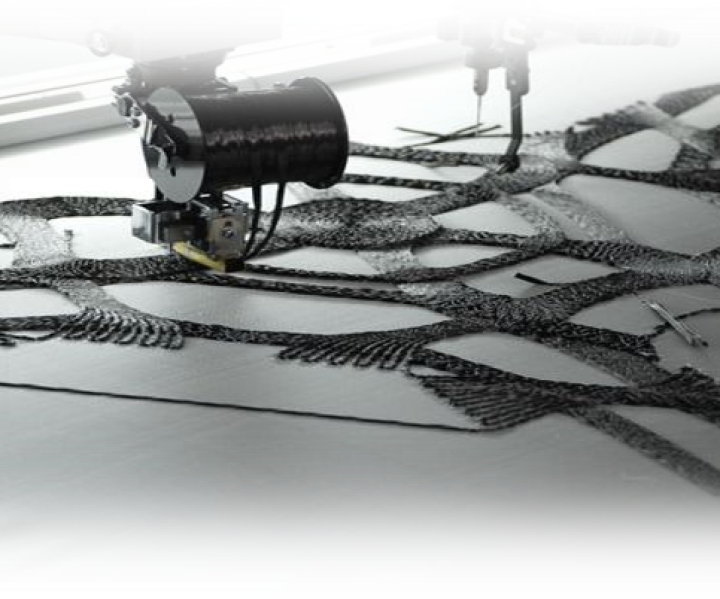

Tailored Fiber Placement Technology

Based on embroidery machinery used in the garment textile industry, the machines have been adapted to deposit and stitch fiber roving material onto a base material. Roving material, mostly common carbon fibers, from about 3.000 up to 50.000 filaments can be applied. The preform is produced continuously by the placement of a single roving.

Shuttle Embroidery Technology

We are specialised in developing and producing smart-textiles with the help of embroidery machines. During this process conductible threads, wires or heating conductors are placed on onto the support material employing computer operated machines. They are then fixed in place with diverse sewing and embroidering techniques which provides for a durable and highly flexible incorporation.

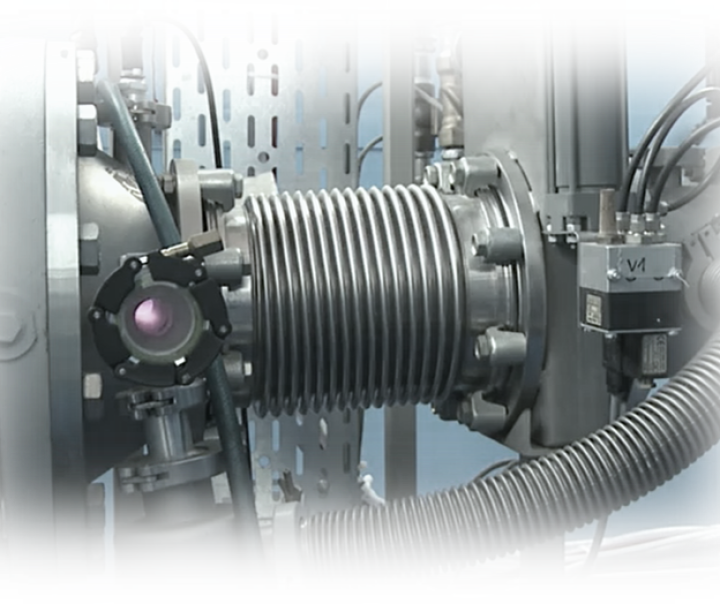

Low-Pressure Plasma-Technology

The presence of a significant number of charge carriers makes plasma electrically conductive so that it responds strongly to electromagnetic fields. Like gas, plasma does not have a definite shape or a definite volume unless enclosed in a container. Unlike gas, under the influence of a magnetic field, it may form structures such as filaments, beams and double layers.

Smart-Textiles and Nanotechnology

130 BILLION EUROS MARKET

The market for wearables using smart textiles is forecast to grow at a CAGR of 132% between 2016 and 2025 representing a Euro 130 billion market. Largely driven by the use of nanotechnologies, this sector has the potential to be one of the largest end users of nano and two dimensional materials such e-textiles, with wearable devices accounting for over half the demand by 2025

Cientifica Ltd. Published Sept. 2016

V-Trion GmbH

Millennium Park 15

6890 Lustenau

Austria

Enrico Grabher

Dr. Gaffar Hossain